Fagerhult uses recycled aluminium for high-volume products — ensuring circular use of resources

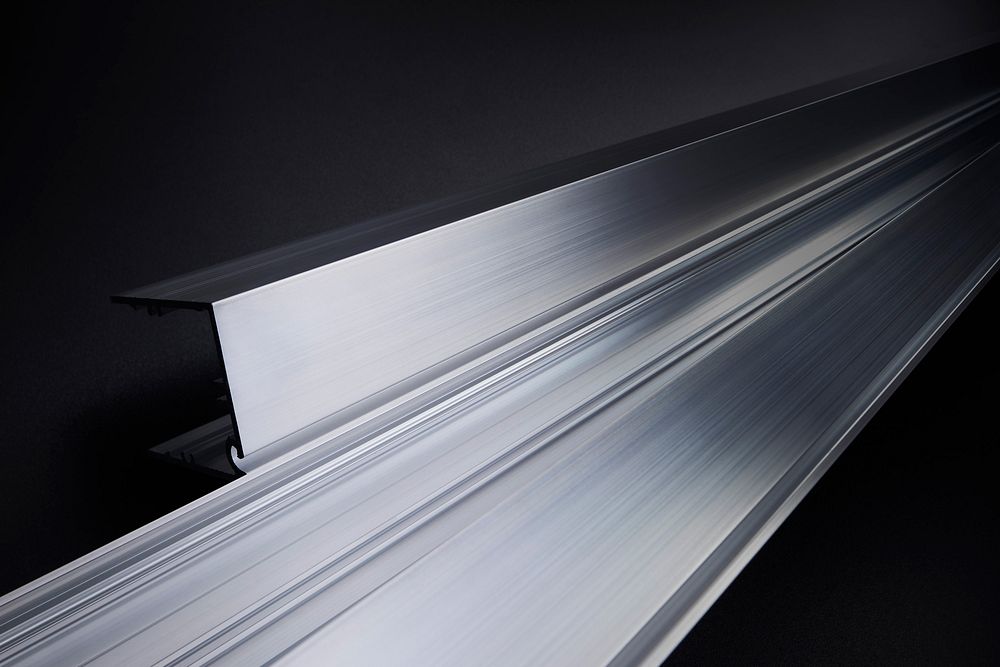

With a focus on reducing its long-term greenhouse gas emissions, Fagerhult now choose extruded aluminium profiles containing 75% recycled material from end users. The material is used for product families manufactured and sold in larger volumes — and where the material can make a real difference. The initiative reduces Fagerhult’s climate footprint by approximately 225 tons of CO2e per year.

Aluminium is a lightweight and durable material that can be reused multiple times if recycled properly. Its environmental impact depends on several factors, including whether it is made from virgin aluminium, how it is produced, whether fossil fuels or renewable energy sources were used in its production, and if it is derived from recycled materials.

Niclas Thulin is Sustainability Manager at Fagerhult:

“We are taking a significant step forward by moving from renewably sourced aluminium to recycled aluminium (post consumer). The Notor family – together with several other product families – is now made of extruded aluminium that is 75% recycled. This results in around 70% lower climate impact than the average impact from European primary aluminium and 88% lower than the global average for primary aluminium*.”

The change affects products sold in larger volumes. The products Notor 65, Notor Recessed, Notor 36, Fjord, Vil, Multilume Hydro, and Sentra are now made of recycled aluminium.

“We intentionally upgrade the materials for our larger product series because it significantly impacts Fagerhult's greenhouse gas emissions. For the Notor family alone, we used approximately 65 kilometres of aluminium profiles in 2024, and nearly all of this volume has now been replaced with recycled material,” says Niclas Thulin.

The change is part of Fagerhult's systematic sustainability work and a considerable step in reducing greenhouse gas emissions in Scope 3: the company's indirect emissions from purchased materials. The Science Based Targets validate Fagerhult's climate targets, and the ambition is to achieve net zero emissions from the entire value chain by 2045.

“This is our most important decision regarding materials, at least with reduced climate impact as the fundamental incentive. The majority of our emissions come from Scope 3, and through this change, we are making a difference where it has the greatest impact. Based on last year's volumes, the switch to recycled aluminium can reduce emissions by approximately 225 tons of carbon dioxide equivalents annually.”

*Climate impact excluding the extrusion process. EPD compared to the European average for primary aluminium (European Aluminium) and the global average for primary aluminium (International Aluminium).

Related News

When material matters – Wrapped adds a new view on sustainable lighting

In a world where every gram of material and every gram of carbon dioxide counts, Wrapped emerges not just as a luminaire – but as a statement. It’s Fagerhult’s most sustainable pendant to date, and it didn’t happen by accident. Every detail, every decision, every material was chosen with intention. Sustainability often starts with a simple question: What is it made of? For Wrapped, the answer is a trio of materials that each carries its own environmental story. Solid board: a familiar friend At Fagerhult, we first met Solid board in 2021 with Multilume Re:Think. But for Wrapped, we’ve taken it further. The material consists of a three-layer construction featuring a 100% recycled core, a renewable FSC-certified top layer, and a thin protective plastic film. All in all, a material that’s 65% recycled – and a 89% reduction in CO₂ emissions compared to virgin extruded aluminium. Image gallery: Solid board Wrapped is made of organic Solid board, recycled aluminium and post-consumer recycled plastic. Reimagining plastic Plastic is often a hot topic in sustainability conversations. But not all plastic is created equal. Wrapped uses post-consumer recycled plastic: the kind that has lived a life before, perhaps as a shampoo bottle or food container. Pre-consumer plastic, on the other hand, is different as it never made it to the shelf. Quote: Josefin Carlsson Aluminium with a past Inside Wrapped, two structural components are made from 100% post-consumer recycled aluminium. This material is also part of a circular infrastructure – and may even have been part of a Notor luminaire once. Compared to virgin aluminium, this choice reduces emissions by 83%. Designing with less - built to last However, sustainability isn’t just about what you use – it’s about how much. At just 900 mm, Wrapped is shorter than a conventional 1200 mm pendant. That reduction in size alone cuts the climate impact by 25%, without compromising the luminaire’s lighting performance. Josefin Carlsson compares the climate impact of products in Fagerhult's Experience Centre in Habo. To understand the impact of Wrapped, it helps to look at where we started. In 2021, Notor 65 – made from virgin aluminium – had a climate impact of 34 kg CO₂e. By 2024, with 75% recycled aluminium, that number was reduced to 25 kg CO₂e. Today, Wrapped comes in at just around 12 kg CO₂e. “That’s a third of the original Notor 65, and half of the current version, and a quiet revolution, measured in kilograms of CO₂e,” says Josefin Carlsson. After its long life – estimated at 100,000 hours – Wrapped is ready for an equally sustainable exit. Its design makes it easy to disassemble, with each material being recyclable and prepared for its next chapter in the circular economy.

Fagerhult announces its official market entry in Germany.

As the Scandinavian market leader for innovative and sustainable lighting solutions, Fagerhult now offers its comprehensive range of products for office applications in Germany. It focuses on lighting solutions that enhance human well-being and help more property owners minimise their climate impact and achieve sustainability targets.“We have planned, prepared, and worked hard for a long time – and collectively strived to move towards taking this step. Now I am pleased to announce that we are finally here,” says Frank Augustsson, MD, Fagerhult. “Germany is Europe’s largest market within the office sector, and we strongly believe our knowledge of smart, sustainable and human-centred lighting can make a difference for both people and the environment, along with sharing our vision of creating Light for better living.”The ongoing phase-out of fluorescent tubes, regulated by EU directives, positions Fagerhult as a key player to help its customers reduce energy consumption and minimise climate impact in offices around Germany."Energy efficiency is high on the agenda in Germany, as it is across Europe. Our ambition is therefore to offer Organic Response with all our lighting solutions. This enables a wireless lighting management system based on integrated sensors to automatically detect and share presence and daylight data. As a result, the light follows people – it is only used when and where it is needed, saving up to 70 % energy from day one."Also, in 2024, the European Parliament voted to revise the Energy Performance of Buildings Directive (EPBD) to reduce the average energy consumption of buildings. This revision mandates the collection of energy performance data, including lighting, in public and commercial buildings. To optimise your facility, smart lighting with Organic Response offers valuable insights that inform strategic decisions about facility management, from energy consumption to space utilisation.A key driver of sustainability is energy efficiency. A life cycle analysis by Fagerhult shows that, depending on the energy mix, the majority of a luminaire’s greenhouse gas emissions occur during the use phase, reaching up to 95% in the German energy mix. In addition to reducing energy consumption, Fagerhult attaches great importance to exploring and using innovative and sustainable materials. By 2030, all newly developed luminaires are to be made from at least 80% renewable or recycled materials.“We hope to find many new and forward-looking collaborations as we introduce Fagerhult and the Swedish Light to Germany,” says Frank Augustsson.